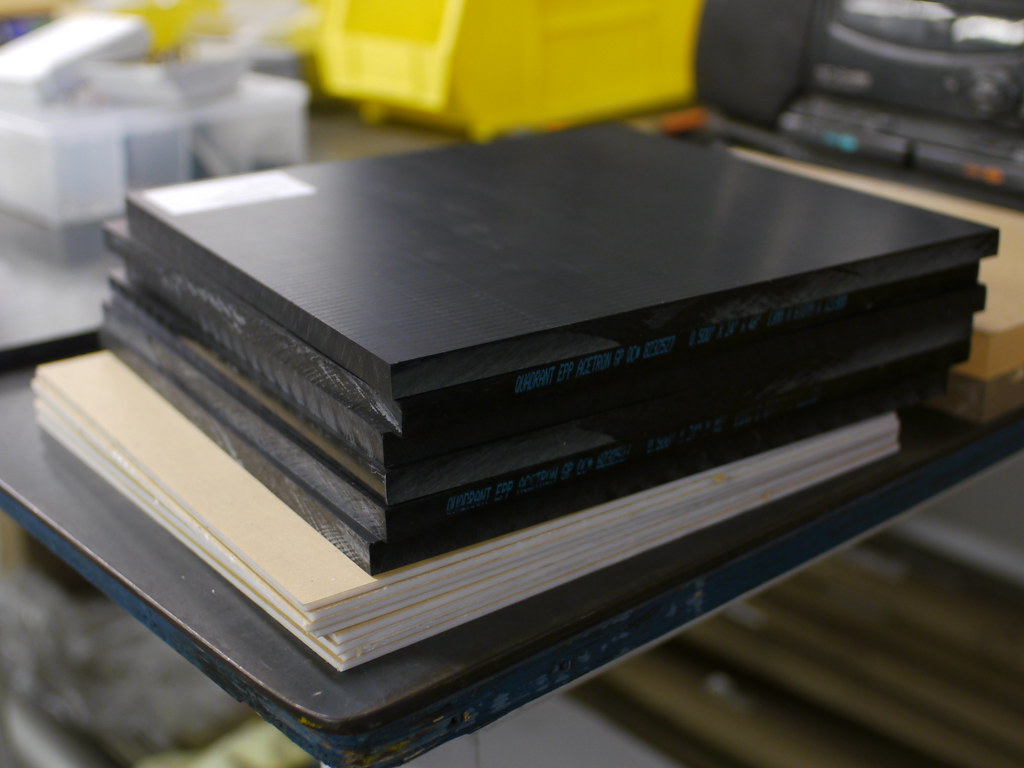

6 square feet of Delrin and 8 square feet of white acrylic ready to be transformed into D|Focuses.

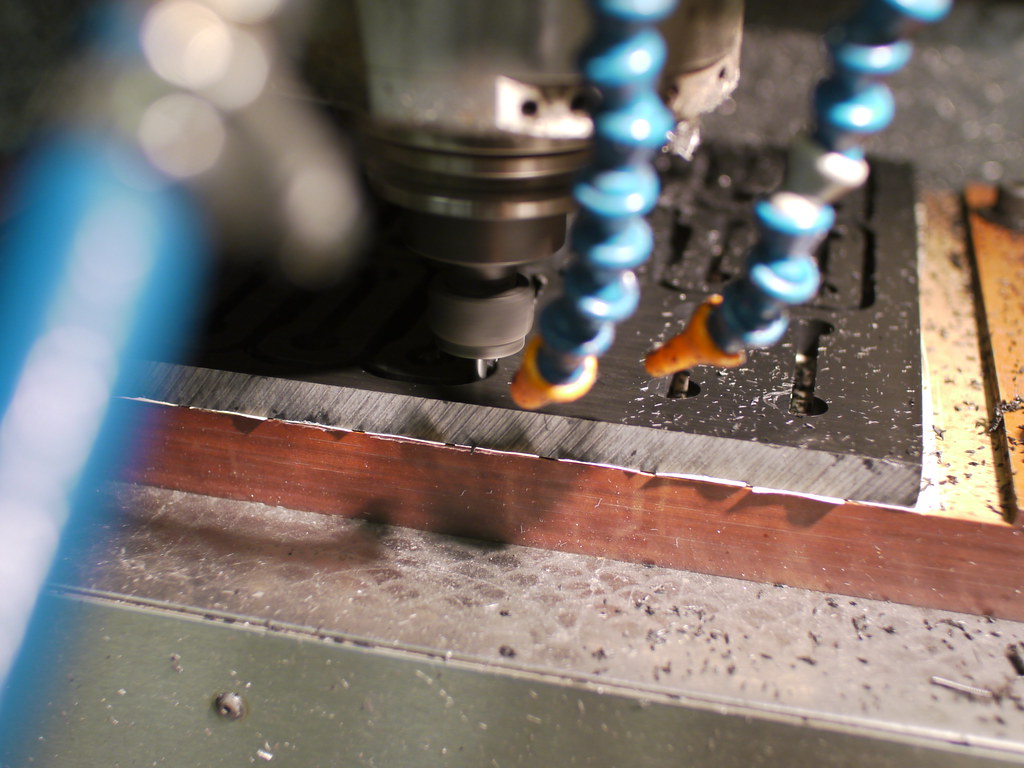

Two batches of rail mounts cut. We can fit 24 of them on a 12 x 12 inch sheet of material. It takes about 2 hours to cut one sheet. The parts not need to be de-burred and drilled.

Here is the CNC Mill at work. We use a 3/16" end mill turning at 5000 rpm. It takes several passes to cut each part out.

Watching the green characters scroll on the screen reminds me of The Matrix.

NOT D|Focuses

Quit laughing and get back to work Tony!

Waiting on Drive Gears

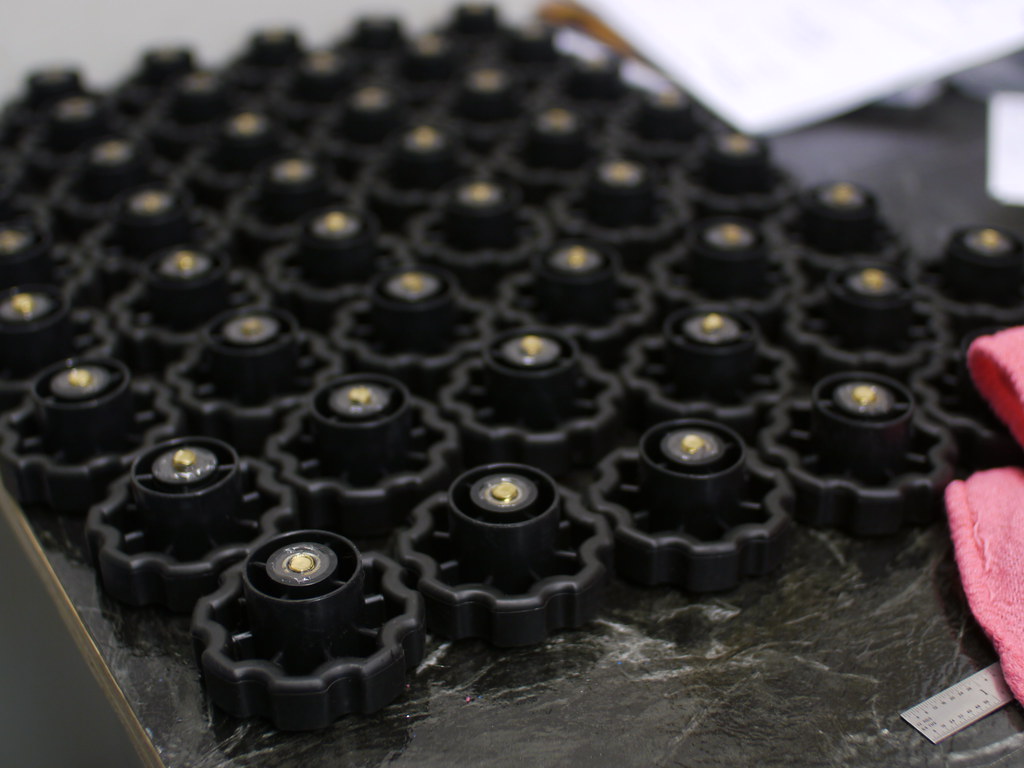

Knobs get a brass insert glued in with JB Weld, then they are drilled, drilled again and tapped for the set screw.

We use a lot of acetone when building D|Focuses. Its perfect for removing any residual oils and sticky residue.

Got to have some tunes!

Here is one of the very first D|Focuses I sold (number 14 actually) in for an upgrade to the new V2.